Real-Life Problem Solving in Dispatching

01/20/2024 - Updated

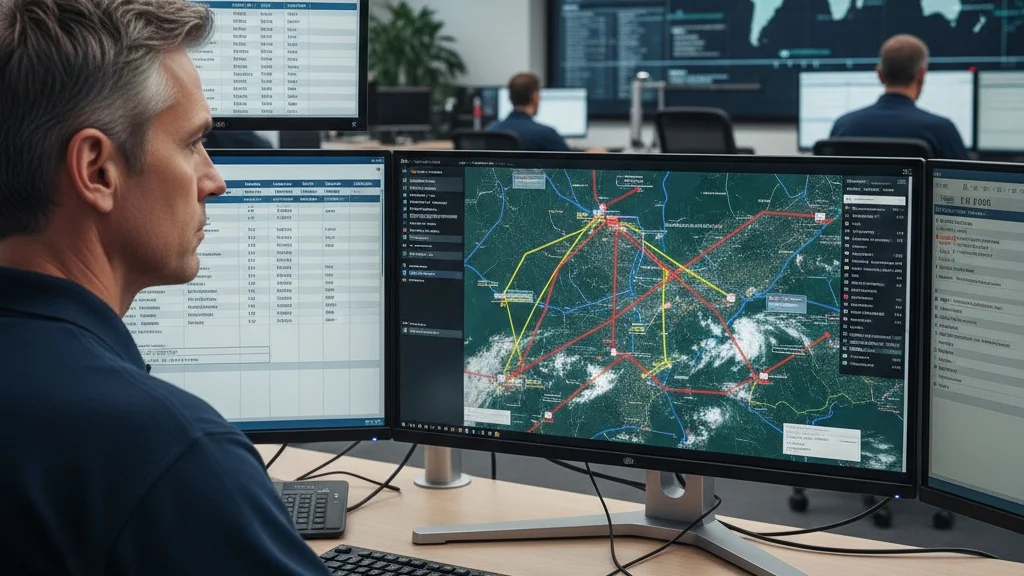

Solving Real-World Dispatching Challenges

This article presents real-life case studies of common dispatching problems and their solutions, providing practical insights and actionable strategies that dispatchers can apply in their daily operations.

Case Study 1: The Weather Emergency

Situation: A major snowstorm was approaching the Midwest, threatening to shut down major highways and delay deliveries for 50+ loads scheduled for the next 48 hours.

The Problem:

- 50 loads scheduled for delivery in the storm path

- Drivers already en route to destinations

- Customers demanding guaranteed delivery times

- Safety concerns for drivers and cargo

- Potential for significant delays and customer complaints

Results:

- Zero driver safety incidents

- 95% customer satisfaction despite delays

- 80% of loads delivered within 24 hours of original schedule

- Stronger customer relationships due to proactive communication

- Proactive communication prevents customer anger

- Safety must always come first

- Alternative solutions can maintain customer satisfaction

- Real-time updates build trust

Case Study 2: The Driver Shortage Crisis

Situation: A regional carrier lost 30% of their drivers in a 3-month period due to retirement and job changes, leaving them unable to cover scheduled loads.

The Problem:

- 30% reduction in driver capacity

- 200+ loads at risk of being delayed or cancelled

- Customer contracts requiring specific delivery times

- Limited time to recruit and train new drivers

- Pressure to maintain service levels

Results:

- 90% of loads delivered on time

- 15% increase in driver retention

- New partner network providing 20% additional capacity

- Customer relationships maintained through transparency

- Proactive driver retention is cheaper than recruitment

- Partner networks provide flexibility

- Transparent communication maintains customer trust

- Load consolidation can improve efficiency

Case Study 3: The Technology Failure

Situation: The dispatch software system crashed during peak hours, leaving dispatchers without access to load information, driver locations, or customer data.

The Problem:

- Complete loss of dispatch software functionality

- 100+ active loads without tracking

- Drivers unable to receive updates or new assignments

- Customers calling for status updates

- No backup systems in place

- Potential for service failures and customer complaints

Results:

- Zero load losses despite system failure

- 100% customer communication maintained

- Systems restored within 4 hours

- New backup procedures implemented

- Always have backup procedures

- Communication is critical during crises

- Manual processes can work temporarily

- Technology failures require quick response

Case Study 4: The Customer Dispute

Situation: A major customer claimed that 15 loads were delivered late and demanded compensation, threatening to terminate the contract.

The Problem:

- Customer claiming 15 late deliveries

- Potential loss of $2M annual contract

- Disagreement over delivery times and causes

- Need to investigate and resolve quickly

- Risk of reputation damage

Results:

- Contract maintained with customer

- Compensation paid only for actual late deliveries

- New communication procedures implemented

- Stronger relationship with customer

- Documentation is critical for disputes

- Face-to-face communication resolves issues better

- Root cause analysis prevents future problems

- Process improvements prevent recurring issues

Case Study 5: The Route Optimization Challenge

Situation: A dispatcher was struggling to optimize routes for 25 loads across 5 states, resulting in high fuel costs and driver dissatisfaction.

The Problem:

- 25 loads across 5 states

- High fuel costs due to inefficient routing

- Driver complaints about long routes

- Customer demands for faster delivery

- Need to balance cost, time, and driver satisfaction

Results:

- 20% reduction in fuel costs

- 15% improvement in delivery times

- 90% driver satisfaction with new routes

- 25% increase in load capacity

- Route optimization saves money and time

- Driver input improves route planning

- Technology tools enhance efficiency

- Communication prevents resistance to changes

Problem-Solving Framework

The 5-Step Problem-Solving Process

Step 1: Define the Problem

- Clearly identify what the problem is

- Gather all relevant information

- Understand the impact and urgency

- Define success criteria

- Identify root causes

- Consider all stakeholders

- Assess available resources

- Evaluate constraints and limitations

- Brainstorm multiple options

- Consider creative alternatives

- Evaluate pros and cons

- Assess feasibility and impact

- Choose the best solution

- Develop implementation plan

- Communicate changes

- Monitor progress

- Measure results

- Gather feedback

- Identify lessons learned

- Implement improvements

Common Problem Categories

Operational Problems

Load Management Issues:

- Load assignment conflicts

- Route optimization challenges

- Capacity constraints

- Delivery scheduling problems

- Customer service issues

- Driver availability

- Performance problems

- Communication issues

- Safety concerns

- Retention challenges

- Delivery complaints

- Communication problems

- Service level disputes

- Billing issues

- Relationship management

Technology Problems

System Failures:

- Software crashes

- Hardware problems

- Network issues

- Data loss

- Integration problems

- Training needs

- Adoption problems

- Workflow disruption

- Performance issues

- Support requirements

External Problems

Weather Issues:

- Storms and natural disasters

- Seasonal challenges

- Route closures

- Safety concerns

- Delivery delays

- Economic changes

- Fuel price fluctuations

- Capacity constraints

- Competition

- Regulatory changes

Problem-Solving Tools and Techniques

Root Cause Analysis

5 Whys Technique:

- Ask "why" five times to get to the root cause

- Helps identify underlying issues

- Prevents addressing symptoms only

- Leads to more effective solutions

- Visual tool for identifying causes

- Categories: People, Process, Technology, Environment

- Helps organize thinking

- Facilitates team discussion

Decision-Making Tools

Decision Matrix:

- Compare multiple options

- Weight different criteria

- Score each option

- Select best choice

- Strengths, Weaknesses, Opportunities, Threats

- Assess internal and external factors

- Identify strategic options

- Make informed decisions

Communication Tools

Stakeholder Analysis:

- Identify all affected parties

- Understand their interests

- Plan communication strategy

- Manage expectations

- Who needs to know what

- When to communicate

- How to communicate

- Follow-up procedures

Prevention Strategies

Proactive Problem Prevention

Early Warning Systems:

- Performance monitoring

- Trend analysis

- Risk assessment

- Alert systems

- Regular reviews

- Standardize procedures

- Regular training

- Performance feedback

- Continuous improvement

- Best practice sharing

- Regular communication

- Proactive service

- Problem prevention

- Value creation

- Trust building

Risk Management

Risk Identification:

- Potential problems

- Impact assessment

- Probability analysis

- Mitigation strategies

- Contingency planning

- Preventive measures

- Backup systems

- Alternative procedures

- Resource allocation

- Training programs

Learning from Problems

Post-Problem Analysis

What Went Wrong:

- Root cause analysis

- Process failures

- Communication breakdowns

- Resource limitations

- External factors

- Successful responses

- Effective solutions

- Good communication

- Team coordination

- Customer handling

- Key insights

- Process improvements

- Training needs

- System enhancements

- Relationship building

Continuous Improvement

Process Updates:

- Revise procedures

- Update training

- Improve systems

- Enhance communication

- Strengthen relationships

- Document lessons

- Share with team

- Update training materials

- Improve processes

- Prevent recurrence

Conclusion

Real-life problem solving in dispatching requires a systematic approach, clear communication, and the ability to think creatively under pressure. Success comes from learning from each problem and continuously improving processes.

Key Success Factors

Pro Tip: Document every problem and solution in a knowledge base. This creates a valuable resource for your team and helps prevent similar problems in the future.

Next Steps

Continue learning about:

- Successful Dispatching Strategies

- Case Studies of Major Trucking Companies

- Lessons from Industry Leaders

Ready to improve your problem-solving skills? Explore our complete knowledge base at Carriversity for comprehensive dispatching strategies and industry insights.

About The Carrier Info Team

Expert team at The Carrier Info, dedicated to providing comprehensive insights and best practices for the trucking and logistics industry.